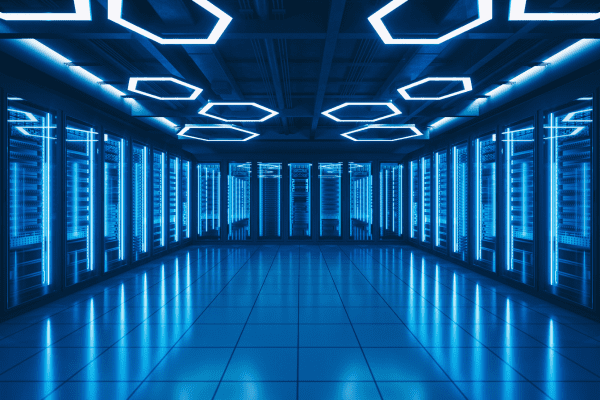

A commercial compressor is a crucial piece of equipment for data centers. Keeping your data center cool is key to extending the life of equipment and reducing the risk of serious incidents, such as fires. Server equipment is the backbone of many data-driven businesses, and it must be kept at a consistent cool temperature.

While regular desktop and laptop computers do generate some waste heat, high-level IT infrastructure is famed for the large amount of heat it puts out. Compressor replacement is an inevitable part of the facility’s life cycle.

Ten Steps to Replacement Readiness for Data Center Commercial Compressors

Modern data center standards suggest that many data centers will be able to operate efficiently without using the extremely low temperatures that were common in past decades. Still, a data center’s climate must be carefully kept at acceptable levels. That also includes relatively low humidity. A good commercial HVAC compressor is essential to its success.

Most of the process of preparing your organization for a data center compressor replacement has little to do with the compressor itself. Instead, you need to be sure that everyone is on the same page so the switchover comes with minimal business disruption and no loss of your critical data.

Here’s how to handle it with less stress:

1. Planning for Compressor Replacement

Ideally, you already have a compressor replacement plan in place that allows you to source a new compressor fast. Consider a remanufactured commercial compressor to save money and accelerate your timeline. Ensure your replacement compressor will fit in the desired space and the cooling output will be adequate.

2. Scheduling Compressor Replacement

Choose a time to execute the replacement that will minimize the effect on the data center’s operations. After-hours and weekends work best for most companies, but it will all depend on your specific services and demand for them. Inform key team members in advance so they can communicate across the organization.

3. Backup Cooling for Your Data Center

Some data centers use duplex cooling with multiple commercial compressors, making it much easier to perform a replacement. If your data center relies on a single compressor, you’ll need a backup cooling solution to run for the duration of the replacement procedure. Consider safety and redundancy before you choose a solution.

4. Pre-Replacement Data Backup

As the point person for the compressor replacement, communicating the schedule clearly in advance is ideal because someone needs to back up any data that’s at risk. Depending on whether you have an on-site IT team or use managed IT services, this could be done with the press of a button or it could take substantially longer.

5. Team Coordination

Team coordination should start as soon as possible, but there should also be a plan to get in touch with all key stakeholders just before your commercial compressor replacement begins. This way, if someone hasn’t gotten the memo, they will still have time to safely shut down any equipment that’s currently being used and you will probably not lose much time.

6. Site Preparation

Site preparation can be done in advance to make it faster and easier for you to get your new compressor to the work site. If you’re using a remanufactured commercial compressor, you don’t have to worry nearly as much – since it uses your existing compressor core, half the work of site preparation is already behind you.

7. Compressor Replacement

When all the right preparation is done in advance, replacing a commercial compressor can be done in as little as a few hours. To make sure everything goes smoothly, talk to your compressor remanufacturing team for advice and best practices to follow for shutting the existing compressor down and bringing the new one online.

8. Post-Replacement Review

Perform standard pre-startup operations including making sure your new compressor is fully supplied with a compatible refrigerant. Test and calibrate the system, bringing it back online systematically. Document any issues or challenges that arise with the compressor replacement process.

9. Compressor Testing and Monitoring

Test the compressor and cooling system to ensure everything is working according to your standards before data center operations begin again. If you use a building management system, be sure the HVAC equipment is completely tied into the system so you can take advantage of built-in analytics.

10. Regular Compressor Maintenance

Last but certainly not least, be sure you have a compressor maintenance plan in place and the right people are ready to get started with it as soon as the end of the week. Compressor maintenance includes daily, weekly, monthly, quarterly, and annual tasks that will extend the service life of your compressor.

Replacing a data center compressor may seem complicated. Get started early and take it one step at a time and it becomes far more manageable. Done right, it prepares your data center for another decade or so of success.