Your choice of a commercial compressor has a significant impact on your work environment for years to come. The compressor is the central component in any commercial refrigeration or HVAC system. Its specifications must be matched to the job at hand and its performance supported with maintenance.

There are many compressor technologies or “architectures” out there. No matter what the underlying principles are, though, all compressors are designed to deliver in certain categories. Thinking in these terms can make a final decision easier:

Performance

A compressor must deliver a consistent output that matches the needs of the worksite. One of the biggest performance mistakes possible is to purchase a compressor that’s larger than you need.

Efficiency

Energy efficiency and environmental impact go hand-in-hand, but it is wise to consider them separately. Commercial compressor manufacturers are racing to deliver better performance at lower energy draw all the time.

Environmental Impact

While every compressor manufacturer strives to adhere to the latest environmental standards, some have a reputation for going above and beyond. Bitzer commercial compressors, for example, were designed under what many consider to be stricter EU environmental rules.

Maintainability

Maintainability will make your life easier by adding months or even years to your compressor’s service life. Being able to open up your compressor and quickly diagnose an issue is worth its weight in gold.

All commercial compressor types have trade-offs in these areas. The selection of the basic technology – reciprocating, screw, centrifugal, etc. – sets the stage for what you can expect. So, one question many people start with is this:

“Is a reciprocating compressor or a rotary compressor better?”

Let’s take a closer look at the two most popular compressor types.

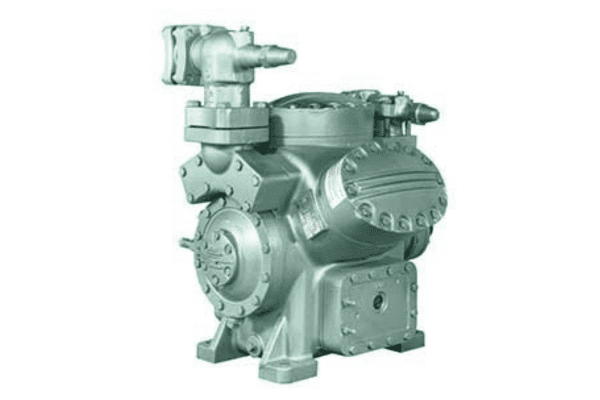

What Is a Reciprocating Compressor?

The main purpose of any compressor is to raise the pressure level of refrigerant gas by compressing it with mechanical or other force. This makes the gas available to the rest of the system. Compressors differ in precisely how they do this.

The reciprocating compressor, also known as the piston compressor, is one of the simplest and earliest commercial compressors. It raises pressure through the mechanical action of a series of pistons. This gets the job done, but it also causes a lot of friction.

Early reciprocating compressors were temperamental and often difficult to keep fully lubricated. Over time, compressor manufacturers have gradually adjusted the size, design, and material composition of the pistons. They have also experimented with new ways to maintain optimal lubrication.

Pros and Cons of a Reciprocating Compressor

Today’s reciprocating compressors are much more reliable than those of the past, but they haven’t changed so much as to be unrecognizable. Although it is not the most efficient of all compressor designs, a reciprocating compressor is straightforward and easy to understand.

Reciprocating compressors tend to be prone to certain specific mechanical issues. This is a drawback, of course, but they are also so familiar that they are very easy to diagnose and often easy to fix. If you have appropriate compressor spare parts, you will often be able to resolve issues easily.

That makes a reciprocating compressor a fair choice in the maintainability category.

A reciprocating compressor is suitable for high pressures, which is not always the case with an otherwise comparable rotary compressor. So, you might find yourself choosing this kind of compressor even if you have the budget for a more advanced model.

One of the biggest advantages to the reciprocating compressor is that it is relatively inexpensive. You can significantly reduce the cost of replacing your rotary compressor by sourcing remanufactured commercial compressors from a company you trust, like Compressors Unlimited.

What Is a Rotary Compressor?

There are actually two distinct types of rotary compressor, the screw or helirotor compressor and the centrifugal compressor. In general, “rotary compressor” refers to the screw type. Screw compressors were developed as a direct answer to the reciprocating compressor and its drawbacks.

A screw compressor is a positive displacement rotary mechanism. It uses two spiral screws (also called rotors) to compress refrigerant gas. The rotors are designed to very tight tolerances and experience far less friction when compared to reciprocating compressors.

Pros and Cons of a Rotary Compressor

A rotary compressor is about 25% more efficient than a reciprocating compressor, which lowers the cost of ownership and the carbon footprint of your cooling system.

Some rotary compressors operate much more quietly than a reciprocating compressor of similar size, giving you more placement options. They are also smaller than comparable reciprocating models.

With less moving parts, a rotary compressor has fewer points of fault. It will tend to encounter fewer issues over time and, thus, usually last longer than a reciprocating compressor.

All in all, a rotary compressor will often be superior to a reciprocating compressor. But it is important to look at the whole work environment and what you wish to achieve before you make your selection.