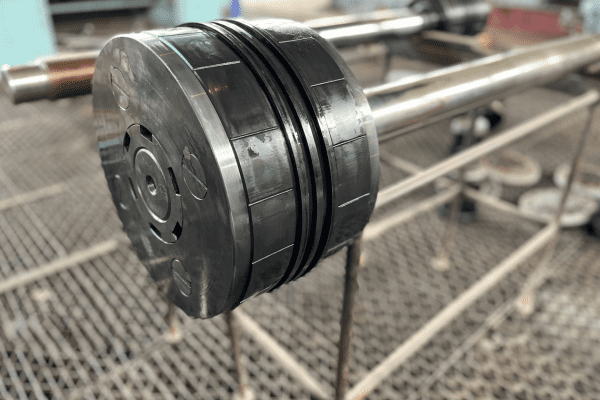

Worn compressor piston rings can be a serious problem for both commercial refrigeration and HVAC systems. Reciprocating compressors (also called piston compressors) rely on these rings. In fact, having worn compressor rings is one of the most common service calls, along with leaky suction or discharge valves.

When the refrigeration or air conditioning equipment is operating, but the resulting temperature is still warm, a service technician is often called to the scene. These situations are common, but they can be tough to diagnose. After all, the system is still producing cooling, which rules out a number of easy fixes.

It’s critical to get to the bottom of the issue fast, and worn commercial compressor piston rings are often the real culprit. In settings such as grocery stores, perishable produce could rise above the optimal temperature, and frozen items might not sell in their intended frozen state. Meats, fish, and poultry may need to be pulled from inventory.

However, worn compressor piston rings are actually much more common with commercial HVAC systems – and that is what the rest of this post will focus on. Once piston rings wear out, you’ll end up with a variety of issues. Other components could get damaged and HVAC cooling service won’t be restored until the matter is resolved.

Diagnosing Worn Compressor Piston Rings

Once the basics, such as refrigerant levels and type, are checked, there’s no single easy solution that points to worn compressor piston rings. Instead, it’s important to do a full system analysis. By reading between the lines, you can identify signs that tell you your compressor piston rings may be worn out.

Some of the signs of compressor piston ring damage include:

Low Condensing (Head) Pressures

A low refrigerant rate through the compressor can be a sign that compressor piston rings have eroded and the compressor’s valves are beginning to leak. Some of the discharge gasses will naturally end up short-cycling in and out of the reciprocating compressor cylinder, creating reduced heat rejection, which leads to this reading.

High Evaporator (Suction) Pressure

Refrigerant vapor is drawn into the compressor’s cylinder during the piston’s downward stroke. With worn out compressor piston rings, the upstroke will also cause some of the very same vapor to sneak right back into the suction line. This points to the overheat-related warping of the valves.

Low Amp Draw

Reduced refrigerant rate through the compressor directly causes low amp draw. This is caused by the unwanted migration of refrigerant during both the suction stroke and the compression stroke. At the same time, the lower head pressure the condenser needs to pump against also cuts down on the amp draw.

Normal or High Condenser Subcooling

Most of the refrigerant will be in the condenser and the receiver, thanks to suction problems caused by piston ring wear and tear. Because the rest of the components are organized in series, there may be noticeably less of the refrigerant reaching other parts – making high condenser subcooling a likely outcome.

Normal or High Superheats

The thermostatic expansion valve (TXV) is one of the components most vulnerable to ongoing issues as a result of the problems caused by compressor piston ring failure. It is not likely to be receiving the refrigerant it needs. High superheats occur when the damage is severe. Superheats might remain normal until that point.

Higher than Normal Discharge Temperatures

Short-cycling of refrigerant vapor (as described above) results in repeated heating of the same discharge gas. The discharge gets hotter and hotter as a result. When the condition reaches its most severe, then the refrigerant flow will be so low that the discharge temperature will rise far below normal levels.

Compressor Piston Rings Can Be Replaced In Some Compressors – But So Can Your Compressor

In a world where most compressor components are no longer intended for field repair, in some compressor models, piston rings are an exception. You should always have the right commercial HVAC compressor piston rings for your system available so you can make a replacement as soon as you identify the issue.

As noted, the trouble caused by worn out compressor piston rings can fly under the radar and might easily be misdiagnosed. For that reason, what seems like a simple matter to fix can actually be the underlying cause of complete compressor failure. When damage is widespread, compressor replacement is the only real option.

When it’s time to replace a commercial HVAC compressor, a remanufactured commercial compressor offers a number of advantages no alternative can beat. Remanufactured commercial HVAC compressors deliver all the performance of an OEM compressor of the same make and model at a fraction of the cost.

Through our comprehensive testing of all a compressor’s functions and replacement of any parts as needed, the remanufactured commercial HVAC compressor you order will deliver eight to ten years of service or more.