At the center of any cooling or refrigeration system is the commercial compressor. All in all, applications of average or larger size would benefit from using a screw compressor over a reciprocating compressor where possible.

A reciprocating compressor suffers significant mechanical wear and tear as it compresses refrigerant gas. On the other hand, a screw compressor virtually eliminates mechanical friction while in operation.

Thus, the higher upfront cost is offset by greater serviceability and longer operational life.

However, any compressor unit slated for deployment in a commercial or industrial environment should be tested under load to ensure it can perform out there in “the real world.” This is true not only of your remanufactured commercial compressors but also of all-new compressors sourced from OEMs.

It is simply a best practice – and demonstrates you are investing your money in quality equipment.

What Does “Testing Under Load” Mean?

“Testing under load” means simulating real conditions to ensure that the equipment will actually work in the environment where you plan to use it. When testing under load, compressor engineers use various means to simulate the kind of load that the device will need to accommodate regularly.

In other words, load testing refers broadly to a kind of stress test. However, load testing is not meant to push the compressor to the limits of its tolerance. Instead, it simply verifies that, when peak operating load is achieved, every part of the system is working as intended.

Load tests are generally performed in a brief, controlled way in an environment calibrated to match the end user’s operating setup. The closer the load is to the maximum the compressor is rated to handle, the more important it is to keep the length of the test within prescribed bounds.

Testing under load is usually one of the last steps in the remanufacturing process. Various other tests, like leak testing, are performed and certified beforehand. Doing the tests in the right order ensures the load test is most likely to be successful – testing a damaged unit under load may cause it to fail.

How Is Testing Under Load Done?

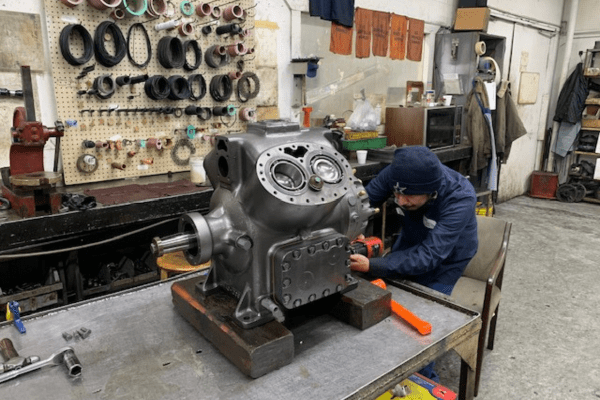

In the past, performance load testing was often performed by connecting the compressor to a whole refrigeration or HVAC system designed with the customer’s needs in mind. This can still be done – a “compressor lab” is often part of a remanufacturing workshop – but it is space-intensive.

In addition to this kind of practical test, performance load testing can also be simulated. This is made much easier by today’s latest generation compressor models. These compressors come with advanced software on board and are compatible with building management systems. This makes it easier to get detailed performance readings from a compressor using electronic equipment.

During a load test, the compressor engineer will collect various forms of data:

- Inlet valve control

- Turndown

- Maximum flow and pressure

- Blow-off control and modulation

- Power consumption

If any of these do not deliver the expected results, the unit is taken offline and the problem investigated. A load test is the best way to identify components that do not perform to their rated standard. This can still occur even when the unit has been completely examined inside and replacements have already been made.

What Other Tests Can a Commercial Compressor Undergo?

There are several different ways to test a commercial compressor’s soundness and performance:

1. Mechanical Run Test

This test focuses on mechanical integrity. It investigates process pressures and temperatures, shaft torque and power, and jacket cooling heat rejection. If a high level of vibration is detected, it might lead to additional testing.

2. Vibration Assessment

A dynamic signal analyzer captures vibration measurements from a range of instruments while the compressor is in operation. Speed reference, data filtering, and run-out compensation are just a few items that can be captured in real time or played back for future analysis.

3. Failure Analysis

Root cause analysis of compressor failures is essential to ensuring that, when returned to work, the unit will perform reliably. Troubleshooting should be done in a professional, carefully controlled lab setting that produces valid results.

Testing Is Critical to Commercial Compressor Remanufacturing

If you are in the market for a remanufactured commercial compressor, it is crucial to make sure your supplier is performing tests that ensure a sound commercial compressor is being delivered. Many organizations that claim to “remanufacture” compressors do minimal or no engineering work, leaving you with an unproven product.

Done right, a remanufactured commercial compressor is one of the fastest and most cost-effective ways to source the equipment your business needs. It is not uncommon to secure a savings of 10%, 20%, or even more compared to buying the same unit from an OEM-affiliated wholesaler. Rigorous testing is a mark of quality that assures you your remanufactured unit is comparable to a new one in every way.