There are many kinds of commercial HVAC compressors, and only one is ideal for your system. Making the right choice from the very beginning is essential. Once your system is fully configured, you should stick with the same make and model of compressor you started with.

Even if you are servicing an established system, it’s still a wise idea to know about the different kinds of compressors out there. Although every compressor operates based on the same basic principles, they have particular ways of performing their function: Compressing the refrigerant gas.

The compressor is the most important part of the system because it makes refrigerant available to all the other processes, facilitating the cooling cycle. When other portions of the system are damaged, it’s the compressor that works harder to compensate, reducing its lifespan in the process.

But the reverse isn’t true: If the compressor stops working, the whole system grinds to a stop.

Luckily, today’s compressors are highly reliable and much more serviceable than those of the past. With a routine maintenance schedule in place, you can expect high-performance standards for eight years or better. Let’s take a closer look at some of the most common compressor types and how they work:

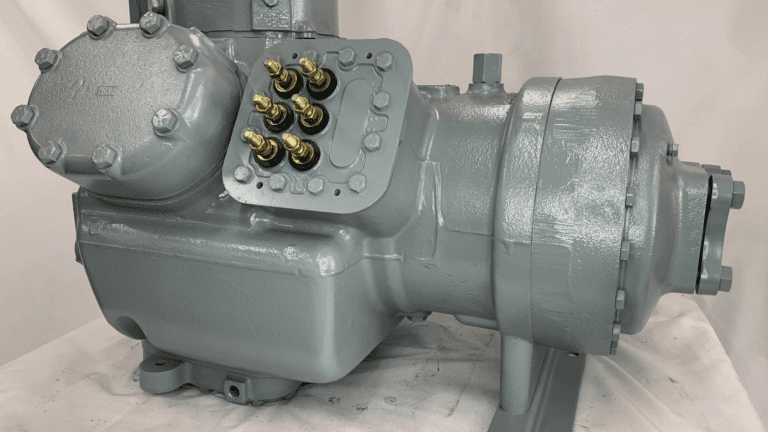

1. Reciprocating (Piston) Compressor

The reciprocating compressor has the longest history and is still very common today. It operates on the principle of positive displacement, using mechanical energy from pistons in motion to increase pressure and compress refrigerant gas.

The reciprocating compressor is easy to understand, looking similar to a combustion engine. The central crankshaft drives an array of anywhere from two to six pistons. The crankshaft, in turn, usually relies on a motor that determines the compressor’s total horsepower.

Reciprocating compressors can be the smallest of all and are generally the least expensive to source. It is important to keep your reciprocating compressor properly lubricated during regular maintenance since the pistons generate a significant amount of friction.

2. Screw (Rotary or Helirotor) Compressor

The screw compressor was developed as a response to engineering challenges of the piston compressor. It uses positive displacement by reducing the space occupied by gas in the compression chamber. A pair of closely mated rotors can facilitate the compression while achieving relatively low friction.

Screw compressors come in a wide variety of sizes and are usually more expensive to source than their piston compressor counterparts. After the piston compressor, the screw compressor is the second most common type of compressor in today’s commercial HVAC systems.

3. Scroll Compressor

A scroll compressor has one fixed scroll that stays in place and is orbited by a second scroll that moves using a swing link. These compressors are highly reliable and efficient. They operate more smoothly and quietly than comparable compressors of other designs.

With fewer moving parts, the scroll compressor also has fewer points of failure than other compressors. There is less torque variation during operation, resulting in quieter output. Scroll compressors are widely used in residential as well as commercial applications.

Are There Other Kinds of Compressors?

These three are the most common compressor designs, but not the only ones. For the biggest and most demanding applications, centrifugal compressors are available. Also known as radial compressors, they work at constant pressure and are extremely large.

Compressor manufacturers are also involved in the process of updating the reciprocating, screw, and scroll compressor designs for the next generation. For example, Danfoss is working on integrating the permanent magnet technology from its centrifugal compressors into its other offerings.

For a commercial HVAC system, you will almost always be choosing between the reciprocating, screw, and scroll compressors. These, in turn, come in a wide variety of sizes. With the top U.S. and global manufacturers to choose from, you are bound to find the right equipment for you.

Remanufactured Commercial Compressors Save Time and Money

No matter what kind of compressor you need, you can often source it faster and less expensively when you choose a remanufactured unit. A remanufactured commercial compressor undergoes an end-to-end re-engineering process that brings it up to all applicable performance and environmental standards.

Remanufacturing goes above and beyond what you might see advertised as “rebuilding.” In fact, there is no definition of a “rebuilt compressor” and it can mean anything. Many facilities leaders have been frustrated to realize they bought a compressor that had only been cleaned up on the outside.

With remanufacturing, you can rest assured that the entire compressor unit has been disassembled, fully cleaned, and had necessary component replacements done by an expert compressor engineer. Afterward, the unit is reassembled and tested under simulated operating conditions.

The result is a unit that maintains all performance and environmental standards and is ready for another 8-10 years of service. No matter what style of compressor you need, most are available in the world of remanufacturing.