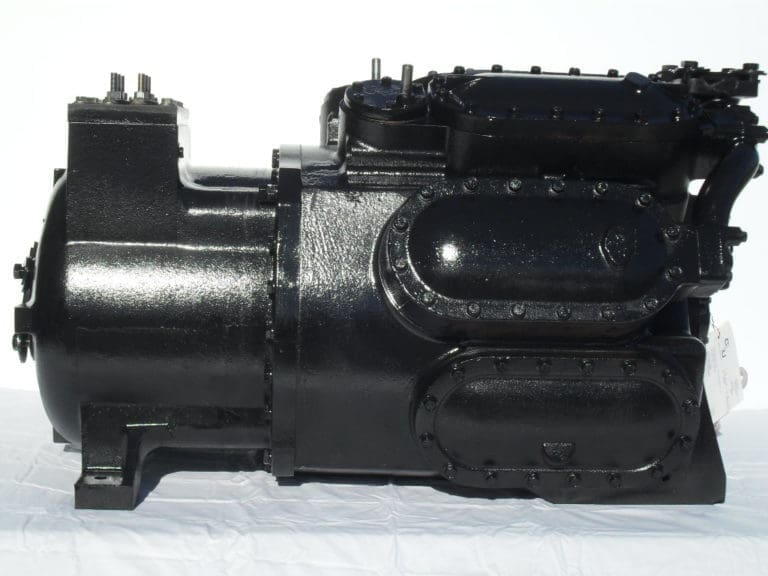

If you have an older or damaged York compressor, it may be possible to rebuild it.

Rebuilding a York AC compressor brings it back to the performance standards you need so you can get your system up and running again. It may be the fastest way to recover from unexpected equipment failure, giving you a longer runway while you source a replacement commercial compressor.

If you are in the situation of needing a rebuilt compressor quickly, it is often practical to take care of the matter yourself. If you buy a “rebuilt compressor” online, it is difficult to know exactly what you’re getting. Many of these compressors have been cleaned or repainted but have not have any other work done to them, unlike that of a remanufactured compressor.

The same is true for York refrigeration compressors and any other kind of compressor out there.

A well-maintained compressor can operate for 8-10 years or more, though performance tends to drop off in the latter years. Often, a compressor that fails before its time is in an operating environment that causes greater vibration than it is designed to handle. Refrigerant flooding and slugging are other issues that can cause a fast failure.

Whatever the case, rebuilding a York AC compressor gives you more options for reaching your goals until you can get a supreme remanufactured commercial compressor to take its place.

What the Compressor Does

The compressor is the core of any commercial air conditioning system. It does the essential mechanical work involved in the compression of the refrigerant gas. It will work harder to compensate for mechanical wear and tear and other issues across the system. But when it fails, the entire air conditioning unit will ground to a halt.

The compressor is often referred to as the heart of the system – and for very good reason.

In recent years, it has not been unusual for large organizations to maintain a stock of backup compressors in the event of an unexpected equipment failure. Farms, meat processing plants, and even large grocery stores, like Kroger can rely on dozens or sometimes hundreds of compressors to maintain perishable products at safe temperatures.

Whatever the case, every day spent without a functional compressor can cost thousands of dollars.

How to Rebuild a York AC Commercial Compressor

York commercial compressors are sturdy and built to last. You do not need to worry as much about causing additional damage as you would with a piece of electronic equipment. Still, be sure the working environment is clean and dry before you begin so no irritants will infiltrate the compressor and cause future issues.

Once the compressor is safely disconnected, there are four basic steps to rebuilding a York compressor:

1. Remove the Oil

Carefully empty the oil from the compressor’s interior.

2. Disassemble the Unit

Remove the shaft nut so you can carefully disassemble the compressor. Your compressor’s service manual will provide you with recommendations on the appropriate tools and internal schematics on what to look for. Some components require special tools for torque and it is not possible to remove them with standard tools.

Take care when removing parts, as they can easily bend if too much force is applied. Be sure you have a suitable working area that allows you to lay out the parts for examination. Laying out components in order will help you when it is time to reinstall them. It is wise to schedule a few hours for the whole process.

3. Examine the Components

Once all the parts have been laid out, it is time to give them a closer look. Most of the time, it will be very easy to spot distortion, damage, or discoloration. Anything out of the ordinary suggests that you should replace the part in question. It may be functional for now, but it is only a matter of time before it blows out. After all we are looking for what is damaged and replace to keep it going until the final solution can be made.

Structurally compromised parts are a major source of leaks. Again, you can consult your service manual for information on replacement parts. If you don’t see any damage – and in many cases, even when you do – you should augment the process by using a magnifying glass to inspect the components more closely.

Should You Get Your Compressor Assessed Professionally?

If you are not familiar with compressor engineering, a professional assessment can help to avoid complications and get to the root of the issue quickly. An experienced compressor technician will be able to notice things that others might overlook. This gets you on the road to the result you need.

*Remember rebuilding, your compressor is only a temporary solution.

York Commercial Compressor Replacements with Remanufactured Compressors

If the compressor is severely damaged, a remanufactured commercial compressor is a great replacement.

A remanufactured compressor has been completely disassembled, all necessary replacements made, cleaned inside and out, and then tested to ensure comparable performance to an all-new unit. This gives you another 8-10 years or more of excellent service at a fraction of the cost of an OEM-affiliated wholesaler.