When it comes to commercial HVAC compressors versus residential compressors, there are some clear similarities. The cooling and refrigeration cycle is always the same, no matter the size or type of equipment. The overall goals of the system are the same, and all kinds of HVAC compressors use the same basic engineering principles.

However, there are differences between commercial HVAC compressors and residential ones. A commercial HVAC compressor isn’t just a “bigger” residential unit. By understanding the differences in actual operating conditions, you can choose the right commercial compressor for your needs.

The differences include:

1. Total Size of the HVAC System and Area Serviced

The size of the HVAC system is often the biggest difference between any commercial and residential application. With that in mind, commercial compressors will usually be larger. A larger system has the capacity to service a much larger area and to do so consistently without interruption, a necessity in most commercial environments.

2. Complexity of the HVAC System

A commercial HVAC system can be much more varied than a residential one, which adds complexity. Even the simple statement that a commercial HVAC compressor is always larger than a residential one isn’t always true, since a commercial HVAC configuration might be set up with several temperature zones and compressors.

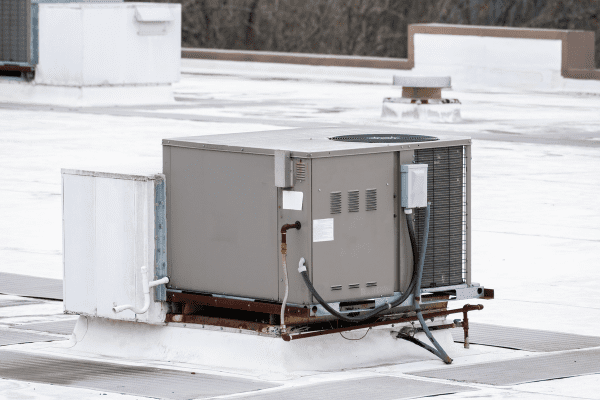

3. Placement of the HVAC Components

The placement of HVAC components is a significant difference between residential AC units are typically placed in a closet or attic. This makes them more accessible when maintenance is needed. On the other hand, HVAC commercial components are generally found on the roof or on a large pad beside the building. This cuts down on noise.

4. Size and Scope of Standard HVAC Equipment

It is no surprise that one more reason why commercial HVAC equipment is found on the roof is because it is so much bigger. Because they must work harder (usually around the clock), commercial HVAC components should be carefully selected for optimal energy use. This is not quite as important in a residential setting.

5. Drainage Methods for HVAC Equipment

Drainage is a key consideration for both residential and commercial HVAC units. Good drainage protects both the HVAC and the building itself. Poor drainage can lead to overflow in a residential unit. It can contribute to a variety of issues, including line leaks and refrigerant loss, in commercial ones.

6. HVAC Installation Considerations and Challenges

Commercial HVAC installations take time and care, but the task is made a little bit easier by the fact that any commercial HVAC system is modular. That makes it easier to get the best performance out of the commercial compressor, as well. By contrast, residential HVAC comes in the form of a single system.

7. Annual Maintenance Costs of the HVAC System

Both commercial HVAC compressors and residential HVAC compressors benefit from maintenance, and the same is true of the surrounding HVAC system. Some parts of commercial HVAC maintenance are similar to residential maintenance, such as the need to clean or replace the air filters on a regular basis.

Replacement Highlights the Biggest Difference Between Residential and Commercial HVAC Compressors

Last but not least, residential compressors of nearly all kinds are not usually intended for residential customers to interact with directly. When they need a new residential compressor, they buy a piece of equipment that has the unit in it. For example, you can see this in common products like kitchen refrigerators and, often, residental air conditioning condensers.

On the other hand, commercial compressors age and wear out over time, then get replaced with a unit of the same make and model. It wouldn’t make any sense if you had to rebuild your commercial HVAC system on the basis of your compressor aging out.

When you need a new commercial HVAC compressor, time and cost are both significant factors. The standard way to deal with the issue in the past has been to work with an OEM wholesaler. However, it’s critical to ask yourself what value you’re getting and if that’s really your only option.

Most commercial HVAC compressors provided by wholesalers aren’t brand new equipment pieces from the OEM. Instead, they have been remanufactured. To get a remanufactured commercial compressor faster and with less expense, go directly to a compressor remanufacturing company.

When you work directly with a compressor remanufacturer, you will trim weeks off your procurement time and potentially thousands of miles off your supply chain. At the same time, you’ll enjoy a discount that can be 10%, 20%, 30% or more – compared to the premium you pay for the OEM brand name.

When you compare commercial HVAC compressors and residential HVAC compressors, there are differences big and small. But when it comes to the strategic needs of your business, commercial compressor replacement is a major difference to be aware of. Remanufactured commercial compressors simply offer the best value.