In the adventurous world of commercial HVAC/R systems, efficient spare parts management is not just a necessity but a strategic imperative. With the smooth functioning of these systems being crucial for business operations across various industries, having a well-organized spare parts inventory can make all the difference between uninterrupted service and costly downtime. Here, we are checking out some effective strategies for managing spare parts inventory for commercial HVAC/R compressors, offering best practices for forecasting needs and optimizing storage.

- Comprehensive Inventory Analysis: The first step towards efficient spare parts management is conducting a thorough inventory analysis. Identify all the components required for your HVAC/R compressors, categorize them based on criticality and usage frequency, and establish minimum and maximum stock levels for each item. This analysis will serve as the foundation for your spare parts management strategy, enabling you to prioritize investments and allocate resources effectively.

- Implement a Computerized Maintenance Management System (CMMS): Leveraging technology is key to streamlining spare parts management. Implementing a CMMS allows you to track equipment maintenance schedules, monitor inventory levels in real time, and generate automated alerts for reordering. By centralizing maintenance data and inventory management processes, CMMS software enhances efficiency and facilitates proactive decision-making.

- Forecasting and Demand Planning: Accurate forecasting is essential for determining the optimal inventory levels of spare parts. Analyze historical data, maintenance records, and equipment performance trends to predict future demand. Consider factors such as seasonality, equipment lifecycle, and lead times for procurement when forecasting needs. Collaborate closely with maintenance teams and suppliers to refine your demand planning process and ensure the timely availability of critical spare parts.

- Prioritize Critical Components: Not all spare parts are created equal. Identify the critical components of your HVAC/R compressors that are essential for maintaining operational continuity. Allocate a higher inventory buffer for these critical items, like spare piston rings, to mitigate the risk of a vendor being out of stock during emergencies. Conduct risk assessments to identify single points of failure and prioritize investments in spare parts accordingly.

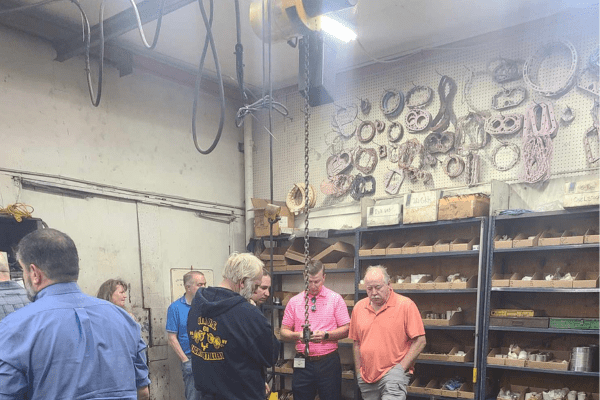

- Vendor Management and Supplier Relationships: Forge strong partnerships with reliable suppliers, like Compressors Unlimited, for spare parts procurement. Maintain open lines of communication with suppliers to stay informed about lead times, pricing changes, and product availability. When appropriate and possible, explore opportunities for vendor-managed inventory (VMI) or consignment stock arrangements to optimize inventory levels and reduce carrying costs.

- Standardization and Rationalization: Standardizing spare parts across different HVAC/R systems can streamline inventory management and reduce complexity. Rationalize your spare parts catalog by eliminating duplicate or obsolete items and consolidating vendors where possible. Adopting a standardized approach not only simplifies inventory tracking but also facilitates economies of scale in procurement.

- Optimize Storage and Warehouse Management: Efficient storage practices are essential for maximizing space utilization and minimizing the risk of inventory errors. Organize your warehouse layout logically, grouping similar items together and utilizing shelving systems or bin locations for easy identification. Implement barcode or RFID technology for inventory tracking and cycle counting to improve accuracy and reduce manual errors.

- Regular Audits and Inventory Reconciliation: Conduct regular audits of your spare parts inventory to ensure accuracy and compliance with established stocking levels. Perform cycle counts and reconcile inventory records with physical stock on a periodic basis to identify discrepancies and address root causes. Use audit findings to refine your spare parts management processes and optimize inventory accuracy.

- Continuous Improvement and Feedback Loop: Spare parts management is an ongoing process that requires continuous improvement and adaptation to changing circumstances. Solicit feedback from maintenance teams, procurement personnel, and other stakeholders to identify areas for optimization and enhancement. Incorporate lessons learned from past experiences and industry best practices into your spare parts management strategy to drive continuous improvement.

Start Effective Spare Parts Management for Your Commercial HVAC/R Compressors

Efficient spare parts management is essential for ensuring the reliability and longevity of commercial HVAC/R systems. By implementing the strategies outlined above, organizations can optimize inventory levels, minimize downtime, and enhance operational efficiency. From proactive forecasting and demand planning to optimizing storage and fostering supplier relationships, effective spare parts management requires a holistic approach that encompasses people, processes, and technology. By embracing these best practices, businesses can achieve cost savings, improve customer satisfaction, and maintain a competitive edge in today’s dynamic marketplace.