The larger the unit, the more important it is to optimize it on two levels:

- Energy consumption, including when the system is at peak and off-peak usage

- Maintenance, in terms of service life and number of component replacements

As a general rule, a screw compressor has fewer points of fault and offers greater mechanical efficiency than a traditional reciprocating compressor. With that in mind, many applications are moving toward screw-type units.

The Basics on Screw Compressor Efficiency

Screw compressors have been around since the 1800s, but have only become a mainstay in commercial refrigeration over the last few decades.

You can find two main approaches: A single screw and double (or twin) screw type.

In either model, there are no valves or rolling element bearings. Refrigerant gas will enter and exit the compressor through ports rather than the valves in reciprocating units. This is key to preserving refrigerant and also ensures the unit has a more compact footprint.

Screw compressors can deliver some impressive benefits:

- Better performance-to-horsepower ratio

- Less mechanical vibration throughout the system

- Lower levels of incidental refrigerant loss

- Fewer moving parts and improved reliability

The modern screw compressor is a very impressive innovation. If one thing is certain in the commercial refrigeration industry, however, it is that things can always be improved. When it comes to superior screw compressor designs, Trane compressors have the answers.

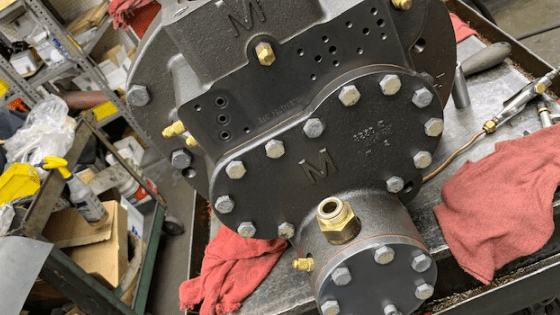

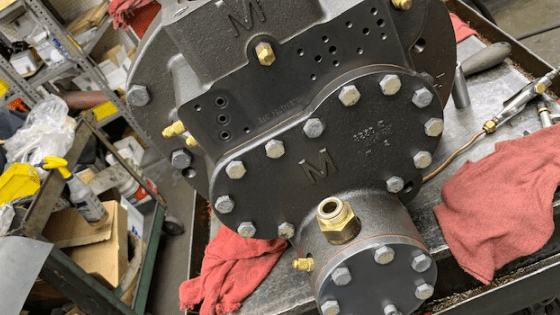

Trane Helirotor Compressors Bring Screw Compressor Technology to the Next Level

Trane is recognized around the world as one of the leading names in modern compressor design and manufacture. Its Helirotor technology – short for helical rotor – takes the basic concepts of the screw compressor and refines them further. The result is an efficient, reliable unit with low ownership costs.

It is also user-friendly and compatible with the latest smart building technologies.

Helirotor compressors have been optimized in ways that directly address the performance limits of the screw compressor. The Trane design incorporates a direct drive, low-speed architecture operating at 3600 revolutions per minute. That goes a long way toward mitigating against mechanical wear and failure.

The Helirotor design improves upon competing models in three other key ways:

1. Dramatic Reduction in Moving Parts

Naturally, the various reciprocating compressors out there all have a different total number of components. On average, though, experts have estimated that these compressors have about 15 times more moving parts than a comparable Helirotor compressor from Trane.

By cutting the internal workings down to their essentials, Trane ensures there are fewer ways a unit can break down. It is also much easier to service. Fewer components mean that what you need should always be readily available from your maintenance provider.

2. Reduced Rate of Refrigerant Loss

Environment-friendly commercial refrigerant can be costly. Likewise, costs and supply are vulnerable to fluctuation, so every drop counts. The Helirotor design significantly reduces incidental loss of refrigerant through better leakage control and superior lubrication.

It also protects against one of the biggest compressor hazards: Liquid slugging.

Liquid slugging is a common problem for reciprocating compressors. Undesired movement of refrigerant through the system can cause significant damage and even lead to failure. All in all, about a dozen different causes can be responsible for liquid slugging.

Trane Helirotor easily ingests small or moderate amounts of liquid refrigerant and avoids slugging.

3. Superior Microprocessor-Based Control

Enhanced control features are fast becoming the “next wave” in compressor technology. Some of the best modern compressors can self-diagnose issues using data received from a wide variety of internal and external sensors. This lets you perform proactive maintenance and extend service life.

Trane’s contribution to this emerging new standard is an impressive one. The Adaptive Microprocessor control enables the unit to adjust internal settings on a very fine-grained basis. Precise changes allow the system to adapt to external conditions and, often, maintain operations when other units would fail.

Events that occur outside of the unit’s tolerance are recorded as part of the onboard analytics system. For facilities using Trane Tracer building-wide energy management, most Helirotor compressors can interface with the system using a single pair of wires. This allows you to make use of industry-leading energy saving options without disrupting any other part of your operations.

For superior performance and efficiency, a screw rotor is a strong investment – and Trane Helirotors are among the best.