York is one of the most trusted names in commercial compressors. With more than 140 years of innovation, it has contributed to the long and storied history of York, Pennsylvania in a way few other brands can match. Plus, it has made its mark globally as a compressor technology leader.

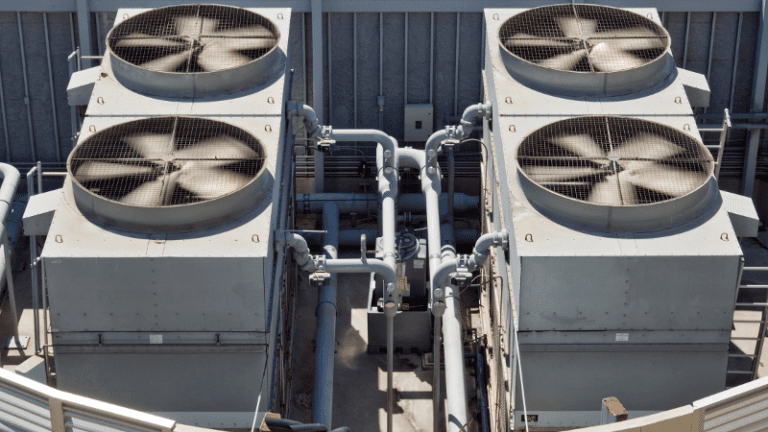

York compressors are found in large commercial HVAC systems across the United States and around the world. Although best known for this purpose, they also show up in specialty chiller systems. Convention centers and hospitality properties love the reliability of the York brand.

Because York continuously iterates on its designs, its portfolio has grown to include a number of compressors suitable for all kinds of situations. The diversity of its offerings helps you optimize your work environment and get the best performance from your equipment.

That said, it can be challenging to find exactly what you need within the expansive York catalog.

Many businesses are using a compressor that could be considered York’s “middle of the road” product, the York JG compressor. Despite not being the most advanced in the York toolkit, it has delivered years of reliable service for large and mid-sized enterprises from coast to coast.

It’s no surprise, then, that many organizations stick with the York JG.

Replacing your existing compressor with a comparable one is the fastest way to keep a system running the way you expect it to. But as York continues to trailblaze in the compressor world, more companies are looking toward its latest offering. That is the incomparable York PA compressor.

If you are wondering whether the York PA compressor is right for you, you’ve come to the right place.

The York PA Is the Groundbreaking Newest Entry in York’s Compressor Lineup

With the speed at which York creates new technological breakthroughs, you might wonder how it all gets done. In the case of the York PA, the team had contact with compressor owners from all over the United States. From these users, they determined the biggest drawbacks of past compressor models.

Even the best technology in the world is still subject to improvement, and York set out to do it.

The result was an intensive and months-long process. By utilizing the insights of top compressor and refrigeration engineers, the York team re-imagined some of the most basic processes behind the York JG. They looked at points of fault and problems that had led to the biggest complaints in the past.

Of course, there are some drawbacks to any technology that can never be perfected. But the York team succeeded in making a significant impact in the jump between the York JG and the York PA. In particular, the new model offers smoother and more reliable loading and unloading across a variety of conditions.

The result is one of the most reliable and most efficient compressors in the market.

Is It Time to Move Up to a York PA Compressor for Your Enterprise?

There’s a wide range of reasons to adopt the York PA in your facility:

1. Efficiency

Most of the major compressor companies have been focusing on energy efficiency and environmental impact in their latest releases. York stands head and shoulders over the rest, providing one of the most efficient compressors of its size class in the York PA. By reducing the amount of electricity you will devote to your compressor, it saves you money and shrinks your carbon footprint.

2. Serviceability

Serviceability has been a driving principle behind many of the best upgrades in compressor technology. The easier a compressor is to diagnose and repair, the longer it can be kept in service and the simpler it is to respond to a crisis. York is already well known for its highly serviceable semi-hermetic compressors. A basic maintenance routine will keep your York PA compressor running for a long time to come.

3. Reliability

If you look at all of the key changes that were made between the York JG and the York PA models, the common theme is making the compressor more reliable. In particular, loading and unloading are now more reliable than ever before. This makes the compressor function better in unusual operating conditions and helps prevent mechanical issues that can wear it out before its time.

Not surprisingly, the York PA has become the flagship of the York brand and is highly in demand. Although OEM-affiliated wholesalers are frequently backed up with York PA orders, you can get one as a remanufactured commercial compressor at a fraction of the regular cost.

A remanufactured commercial compressor undergoes a thorough engineering process that ensures it is ready to deliver years of exceptional service aligned with all OEM performance and environmental standards. It is the fastest and least costly way to benefit from the York PA as soon as possible.