Screw compressors, also known as helirotor compressors, are some of the most efficient compressors you can buy today. Originally designed to provide for an alternative to the reciprocating compressor, screw compressors have become known for a high-level of efficiency and impressive output.

Because a screw compressor operates at a higher RPM than a reciprocating compressor, it’s important that it be manufactured according to the highest standards. Several companies have tried their hand at the screw compressor over the years, but Trane stands out for its exceptional performance.

While there are many options to choose from out there, more and more enterprises have discovered a Trane system using screw compressors is the best option to meet their needs. No matter if you have a highly demanding commercial or industrial environment, Trane offers products that may work for you.

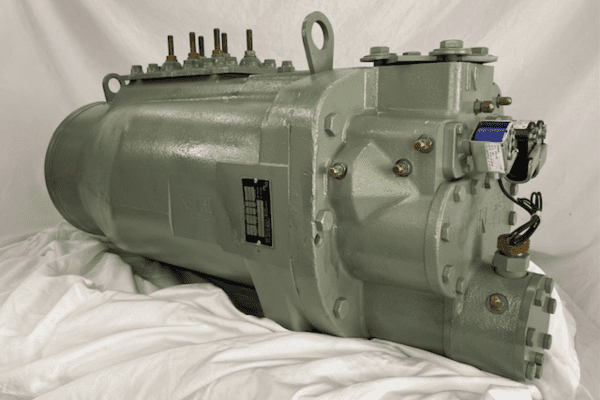

When you are replacing an existing screw compressor, it’s crucial to make sure you only use the exact same make and model you have. This is another area where Trane goes above and beyond. The Trane CHHP compressor is one of the most frequently requested by customers of Compressors Unlimited.

Trane’s CHHP Compressor Model Can Meet Even the Most Stringent Needs

CHHP corresponds to Trane’s GP2 series screw compressor. It comes in a full range of sizes including the 70, 85, 100, and 120 ton models.

Let’s consider just a few of the many reasons it’s so popular today:

1. Direct Drive Construction

From the very beginning, engineers have realized that fewer moving parts in a compressor means fewer points of failure. A direct-drive screw compressor like the CHHP beats both reciprocating compressors and gear-drive screw compressors in this department. With simplicity comes greater reliability.

2. Semi-Hermetic Design

The Trane CHHP screw compressor benefits from its semi-hermetic design by allowing for the replacement of serviceable parts. The internal oil filter, load and unloader valves and coils are all easily accessible. However, it should be noted that due to the close tolerances and tools needed, some repairs and/or maintenance tasks should not be completed in the field.

3. Smooth Unloading

The partial load operation is one of the best ways to extend a compressor’s life while also ensuring it stays highly efficient under any conditions it encounters. System temperatures can be held within half a degree Fahrenheit of its settings, which makes the CHHP ideal when cooling loads are an essential variable.

4. Low Torque

Across the board, Trane screw compressors are known for motors and rotors with a smaller diameter than many competing brands. This helps you easily avoid excessive heat build-up. This not only affects compressors directly but improves the longevity of key components throughout the entire system.

5. Matches Existing Equipment

It’s never advised to mix and match components in a major building system like your HVAC or in any kind of commercial refrigeration application. However, with a Trane compressor, you know you’re getting predictable and reliable performance from your other Trane chiller components.

6. Wide Selection of Trane Screw Compressors

There are four different sizes of the Trane CHHP screw compressor. This means that there is a model that’s just right for nearly any application. If the CHHP screw compressor won’t serve your needs, there are many other Trane screw compressors that all incorporate the engineering wisdom of this leading brand.

With a Remanufactured Commercial Compressor, You Don’t Have to Wait

The average commercial compressor will last between eight and ten years with appropriate care and maintenance. In the first half of its life, the compressor is rarely the culprit if something goes wrong with the system. As years go by, however, it will lose efficiency and may perform erratically at times.

It is critical not to overestimate how long your existing commercial compressor will continue to function.

Unfortunately, even organizations that strive to take the right steps at the right time often find they are behind the curve. International supply chain problems can leave you waiting for weeks or even months when you need a replacement compressor urgently.

With a remanufactured commercial compressor, a compressor core is used as the center of your new compressor. The compressor is completely disassembled, cleaned inside and out, multiple measurements are checked both on the bare core and on all parts to ensure they are still within tolerances, then all non-conforming parts are replaced. Component replacements are done as necessary to return the unit to “like new” operation.

To ensure a remanufactured commercial compressor delivers on all your existing environmental and performance commitments, it is tested throughout the process. The final tests simulate actual operating conditions. This way, you know the compressor you receive is ready for action.

When it comes to a replacement Trane compressor, you don’t have to ‘hope for the best.’ Through the power of remanufacturing, you can get the unit you need in days instead of months, at a deep discount.