In the history of commercial compressors, you’ll find many different technologies. Looking back at the earliest commercial compressors, the reciprocating style comes to mind. It was followed by the screw compressor, designed to address the engineering faults and challenges of the reciprocating model.

Today, the vast majority of commercial compressors are reciprocal or screw-type compressors. Only the very largest commercial compressors use centrifugal force as their main operating principle. But there is another dimension to look at when you consider which kind of compressor you want to use.

You could consider this other dimension the architecture underlying your compressor technology.

The three different compressor architectures are:

- Hermetic

- Semi-Hermetic

- Open

Reciprocating compressors, screw compressors, and all other types can be found that conform to these three designs. Of course, certain technologies and applications are associated with certain approaches. Whichever architecture you choose, it will have a significant impact on how your system operates.

Likewise, it is very difficult to “start over” once you have chosen and deployed a compressor. With that in mind, it is important to make the right choice the first time. When it comes to refrigeration or HVAC systems at a large scale, that “right choice” is always an informed choice.

What Is a Hermetic Compressor?

Hermetic compressor describes a style of compressor you are less likely to see in large industrial or commercial applications, but it is still used on occasion. A hermetic compressor is completely sealed away from the environment, with the casing welded shut. It cannot be accessed by any means.

On its own, “hermetic” usually means an airtight seal. In the context of a compressor, it refers to the way the compressor is completely separated from the external operating environment. You don’t need to worry about spillage or infiltration of debris, which cuts down on flooding and slugging.

However, there are serious drawbacks to a hermetic compressor that limit the way it is used, especially in demanding environments. Hermetic compressors are usually restricted to smaller systems. They are much more common in consumer goods, such as home refrigerators.

One of the most common places to see a hermetic compressor at a business is small refrigerated displays for grocery stores. These can be “chained together” to operate effectively even when one compressor underperforms or fails. The small, light hermetic compressor lends itself to this use.

For situations where you need to maximize performance and efficiency, the hermetic compressor often gets passed over. In the event of a mechanical issue, it cannot be opened for service. A problem might be simple and easy to fix, but your only option is to replace the compressor completely.

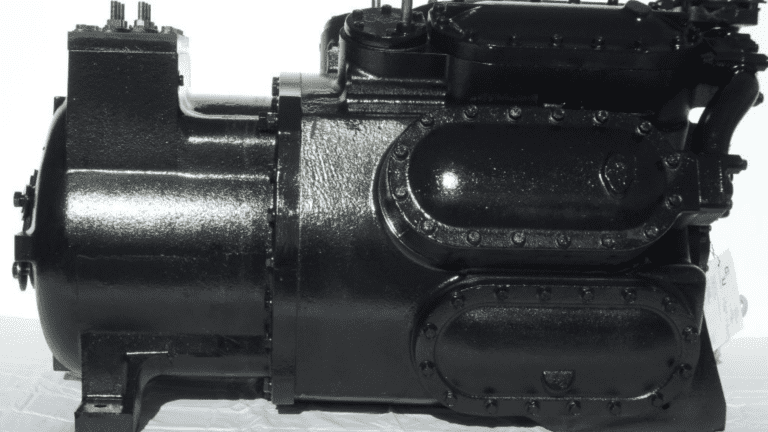

What Is a Semi-Hermetic Compressor?

As with a hermetic compressor, a semi-hermetic compressor has both the compressor and the motor fully protected from the environment within a sealed shell. Unlike the hermetic compressor, though, semi-hermetic models are designed so they can be opened for diagnosis and periodic maintenance.

Maintenance truly is the key to extending the service life of a compressor and thus saving thousands of dollars in the long run. While no compressor will last forever, modern compressors can perform at full efficiency deep into their operational lifespan as long as they are getting the right maintenance.

With that in mind, the semi-hermetic compressor has displaced most other options as a common and reliable go-to for most approaches. This is even true when it comes to smaller reciprocating units that would have been designed as hermetic compressors in the past.

What Is an Open Compressor?

In an open compressor, the compressor itself and the motor are not protected from the elements in any way. While it is possible to service this kind of compressor, the environment must be carefully controlled or the compressor will fail due to dirt, debris, chemicals, and other contaminants.

What Type of Commercial Compressor Should You Use?

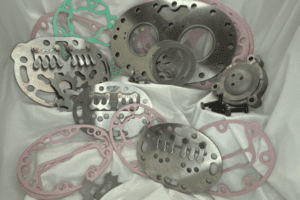

If you have a choice between a hermetic and semi-hermetic compressor with the same performance specifications, it is wise to go with the semi-hermetic compressor. Ensure you always have the right spare parts on hand so you can quickly resolve any issues and control downtime.

If you need to use a hermetic compressor for any reason, it’s a wise idea to reduce your dependence on a single unit. Have a replacement commercial compressor at the ready to minimize the business impact of any compressor failure.

When you choose a remanufactured commercial compressor, you can easily source a unit with the same performance and longevity you expect from an all-new OEM product. Remanufactured compressors can often be 10%, 20%, or 30% less expensive and may arrive at your workplace weeks sooner, than that of an OEM product.

No matter what kind of compressor technology or architecture you decide on, your remanufacturing team can help you get the most value and the longest life from your selection.