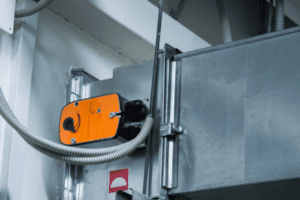

Many industrial workplaces rely on precise temperature control to function. A large, complex HVAC system may be required to maintain required temperatures and support indoor air quality across a facility. Likewise, refrigeration may be necessary for chemicals, medication, and other perishables.

From large dairies to foundries, industrial enterprises rely on having the right compressor to help their cooling systems function. The industrial compressor plays a central role in all refrigeration systems.

Each individual refrigeration device has its own compressor. These compressors are much larger and usually more complex than the ones used in consumer appliances.

Consumer refrigerators, for example, generally use a hermetic compressor. Because it is fully sealed, it is not intended to be accessed for service – when it breaks down, it must be replaced. On the contrary, an industrial compressor should be maintained regularly.

Refrigeration cannot function without a compressor, but what, precisely, does the compressor do?

Basics of the Industrial Refrigeration Compressor

Refrigerant enters the compressor as the first step in the refrigeration cycle. Within the compressor, the refrigerant is pressurized and superheated. At appropriate pressure, it leaves the compressor and enters the condenser, where it traverses a series of tubes. Cool air is blown across the tubes by a fan.

Heat transfers from the tubing to the cooler air flowing past, causing the hot vapor refrigerant to turn into a liquid. As it passes through the condenser, it enters a metering device or expansion valve. Pressure is maintained on the inlet side while being reduced on the outlet side.

Once it reaches a cool state of low pressure, the liquid refrigerant enters the evaporation phase, where it absorbs heat from warmer air and reduces temperatures in the conditioned space.

The industrial compressor is central to this entire process. It ensures all the other parts of the system can work as intended. As the name suggests, the compressor works to compress the refrigerant gas, using mechanical or other force to raise its temperature and pressure levels.

In effect, the compressor exists to make the gas available to the rest of the cooling system. Without the compression step, it would not be possible to moderate the flow of refrigerant and control temperatures in the conditioned space. The industrial compressor is so central, it is thought of as the system’s “heart.”

As other components of a system age and wear out, the compressor must work harder to compensate. However, no other component can do the work of the compressor. When it comes to a stop, the whole system will follow. Luckily, sudden and unexpected compressor failures are rare.

Different Types of Industrial Refrigeration Compressor

There are a few different categories of industrial compressors to be aware of.

1. Industrial Reciprocating Compressor

The simplest of industrial compressor types is the piston or reciprocating compressor. In the past, these compressors were subject to early failure because of the continuous mechanical forces at work. Today’s reciprocating compressors are much more durable.

2. Industrial Screw Compressor (Helirotor or Rotary Compressor)

The rotary or screw compressor was developed as a significant step up from the reciprocating compressor. With a rotary screw moving in a continuous sweeping motion, the system can operate at consistent levels without much surging of flow. There is less friction within the unit as compared to a reciprocating compressor and it is far easier to keep it fully lubricated.

3. Industrial Centrifugal Compressor

The centrifugal compressor is another type of rotary compressor. Unlike the screw compressor, which can be found in a variety of sizes and applications, the centrifugal compressor is almost always seen in demanding industrial environments. On average, it is among the largest compressors sold.

Centrifugal compressors elevate the refrigerant pressure by applying kinetic energy as the gas flows through an impeller. Each individual centrifugal compressor is optimized through a specific impeller design suited to the application. They are found in industries including automotive, pharmaceuticals, textiles, power, renewables, wastewater treatment, and chemical manufacturing, among others.

Make Sure Your Industrial Refrigeration Compressor Is Right for You

When it comes to the industrial compressor, bigger is not usually better. Instead, the compressor needs to be fitted precisely to the task at hand. Its size, throughput, and features like partial load operation must be selected with the working environment in mind.

A compressor that is not large enough will not consistently deliver the required performance, while one that is too large will have a higher overall cost of ownership and tend to be inefficient. In both cases, early failure is possible. Strategically, it’s crucial to extend a compressor’s life for as long as possible while reducing the cost of replacement.

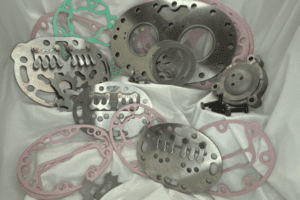

When compressor replacement is necessary, a remanufactured industrial compressor delivers the same performance and environmental standards of an all-new unit. Not only is it far less expensive, but it can be delivered weeks sooner.