When it’s time to purchase a replacement commercial compressor, you’ll usually need one exactly like the one that’s left service – down to the brand and model. That can be a challenge, as OEM-affiliated wholesalers may take months to provide a new compressor.

Often, time is of the essence when a compressor fails … or even just shows signs of problems.

In general, you can expect 7-10 years of reliable service from a new compressor, whether you buy from the OEM or choose a reliable remanufacturing firm. But problems in the operating environment can cause issues, like flooding and slugging, that stop compressors before their time.

Good maintenance practices extend a compressor’s service life, but there is a limit.

In most commercial enterprises, especially those open to the public, your reputation relies on an effective compressor. The compressor does the majority of the mechanical work to make the refrigerant gas available to the rest of the system. When it stops, so does everything else.

Losing compressor function means your HVAC can’t cool or heat the air – both settings rely on the same fundamental processes that affect the refrigerant. From there, it’s only a matter of time before the environment becomes too stifling for productivity and won’t attract much foot traffic, either.

At industrial concerns, this effect can be even more pronounced. Many industrial companies need to hold the work environment at a certain temperature no matter what the outside climate is like. Without the HVAC system running strong, you’re at the mercy of whatever weather conditions might strike.

What’s the solution? A remanufactured commercial compressor.

Benefits of Using Remanufactured Compressors from a Quality Remanufacturing Firm

The remanufacturing process shouldn’t be mistaken for “refurbishing” or “rebuilding” a compressor.

The problem with those two very common terms is that there’s no real definition for either one of them. In some cases, companies will claim that they’ve rebuilt a compressor when all they’ve done is clean up the exterior. No work is done on the inside, leaving any faulty components in place.

Luckily, it’s easy to spot the risk if a company doesn’t offer a warranty and stand behind its work!

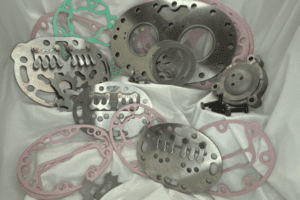

On the other hand, a true remanufactured compressor goes through a thorough, proven process. Here at Compressors Unlimited, that includes more than a dozen steps. Each one is carried out by a qualified compressor technician who has the skills and the experience to get the job done right.

All in all, it means re-engineering the product to the standards of the Original Equipment Manufacturer using a combination of requalified, repaired, and new parts and components. At the same time, any parts that are old, faulty, or obsolete need to be replaced, updating the compressor’s specifications.

By replacing such parts, you end up with a unit that offers comparable performance and longevity to the high-priced OEM unit that may take months to ship from a wholesaler. The ideal is to provide you with the same 7-10 year service lifespan that you would get if you chose to go direct – at a fraction of the cost.

The Big Difference Between Remanufactured and Refurbished

“Remanufacturing” is a specific discipline in the world of compressor engineering. A good compressor remanufacturer will uphold the highest quality output by developing a reliable, documented process for servicing and updating a compressor from top to bottom.

This detailed recovery process is necessary for a variety of reasons.

One of the biggest ones is the fact that compressor environmental rules are always changing. If you do not take a complete view of the compressor and make sure the components are fully up-to-date, you will not be able to reduce your energy usage, which results in higher costs and more emissions.

At Compressors Unlimited, we meet the EPA’s GO GREEN regulations. We’re able to help you maintain your commitment to the environment while we also reduce waste and promote conservation. Each time a compressor component is safely returned to service, it means fewer will need to be manufactured.

Likewise, we have detailed environmental guidelines for disposal of oil and any other byproducts that arise during our work. You can rest assured waste is handled in accordance with today’s best practices. That not only protects your company’s reputation, it will help you sleep well at night!

HVAC Compressor Replacement Products from a Source You Can Count On

Our HVAC compressor replacement products undergo a series of functional and environmental tests. At each stage, we are able to recognize and resolve issues before they can affect the system. We deliver a quality end product that handles your application flawlessly.

You can read about our remanufacturing process here. No matter what remanufacturing partner you choose, be sure they are straightforward about the work they do and offer you a warranty you can trust.

*This blog has been updated from its original posting.