When servicing a commercial compressor, you might run into all kinds of conditions that you don’t expect. Documentation is often limited, so it can be difficult to know exactly what’s going on unless you’re an experienced compressor technician or have access to one.

We always recommend finding a team of trusted compressor engineers to assist with maintenance and help you get the most value from your compressors. With the right maintenance, you can expect many years of reliable service from your compressor.

When compressors fail suddenly “out of the blue,” it almost always indicates that there has been a maintenance oversight somewhere down the line. More rarely, there may be a problem within the operating environment, such as electrical issues or environmental contamination.

Whatever the case, you will see the most value from your compressor when you stay informed.

But it can be tough to get the answers you want, and you might not always have time to crawl through dozens of forum posts. Likewise, the information you find online may not apply directly to your specific compressor or your application. That can easily lead you in the wrong direction.

With that in mind, we’ve developed this list of common compressor questions and answers.

These commercial compressor FAQs will help you get off to the right start when you diagnose your unit.

Commercial Compressor Frequently Asked Questions

1. What is the meaning of LRA in a compressor?

“LRA” stands for locked rotor amps. This is a measure of the current draw you can expect from the unit’s motor under starting conditions when you apply full voltage. LRA conditions last for only a few seconds during a unit’s startup phase. You will be able to find this information on a plate on the compressor unit itself. It can also be tested with a clamp meter. Compressors should not draw the full LRA after startup!

All in all, LRA is about five to seven times higher than the normal operating current of the compressor. LRA is stamped onto the compressor because it must remain consistent throughout the unit’s service lifetime, and you can use it to determine other facts about the compressor.

If the information plate on your compressor is incomplete, you may be able to estimate the LRA without it. For a single-phase unit, the following equation can get you there: LRA = 1000* (kVA/HP)/Voltage.

2. What is the meaning of RLA in a compressor?

Not to be confused with LRA, “RLA” refers to rated load amps. It is also called running load amps or full load amps (FLA). You can deduce an estimated RLA in a compressor if you have the LRA figure. The rule of thumb is to divide the LRA by six. Some textbooks suggest the precise figure is 5.56.

3. What voltage do I run my commercial compressor on?

Check the unit plate for the precise voltage and amps before bringing your compressor online.

4. How do I check my compressor’s BTU capacity from an LRA number?

Start with the model and serial number. Within the model number, the three-digit code refers to the BTU capacity. You can determine the compressor’s tonnage from here: Every 12,000 BTUs equals one ton. For example, a 3-ton compressor unit would have the number 036.

5. What is the difference between a T1 and a T3 compressor?

The “T” rating on a commercial compressor refers to the specific climate where it is intended to be used. T1 is a moderate climate, T2 is a cold climate, and T3 is a hot climate. They are designed to operate in the following temperature ranges:

- T3 (“Hot”): 21°C to 52°C

- T2 (“Cold”): 10°C to 35°C

- T1 (“Moderate”): 18°C to 43°C

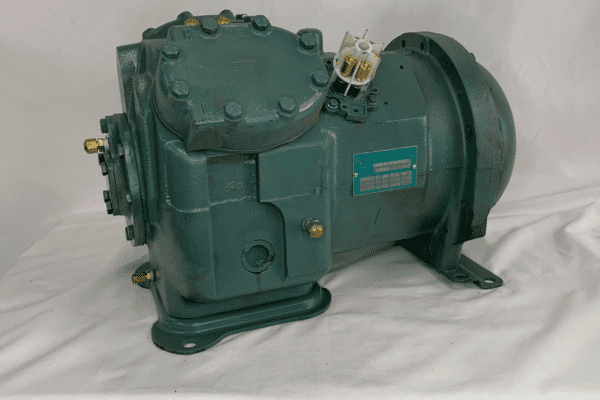

6. What is the difference between a new commercial compressor and a remanufactured commercial compressor?

A properly remanufactured compressor should have no difference in either performance or operating efficiency when deployed in real world conditions. The remanufacturing process should account for all damaged components, completely replace them, and fully test the unit.

From a business standpoint, a remanufactured commercial compressor is frequently around 30% less expensive than an all-new commercial compressor from an OEM-affiliated wholesaler. Likewise, the remanufactured unit can often be sourced several weeks sooner, which is essential in an emergency.

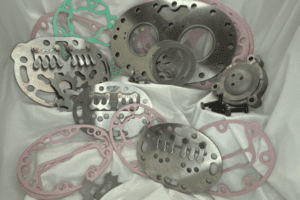

7. What are the standard maintenance procedures for a remanufactured commercial compressor?

Compressor maintenance should be performed regularly along with the maintenance of your whole air conditioning or refrigeration system. Maintenance is usually broken down into weekly, monthly, quarterly, and annual tasks. You should monitor the operating environment daily for any problems.

To find out more, check out our compressor maintenance resources:

We hope this compressor maintenance FAQ has been of value to you. If you need personalized advice on maintaining your compressor, contact your trusted compressor remanufacturing team.