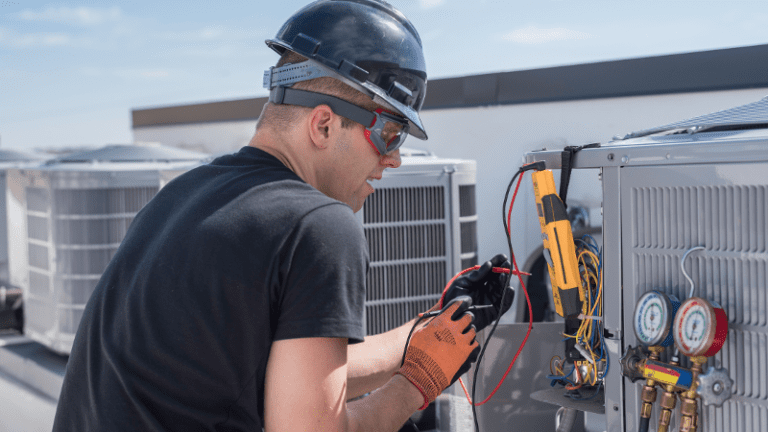

Commercial HVAC failure can come in many forms. By and large, the commercial compressor unit itself is rarely the guilty party. Commercial compressor failure is the most serious HVAC problem you can have. It also tends to be the easiest to diagnose. But there are many other issues that could arise.

Glitches that have nothing to do with the compressor unit can bring the HVAC system to a screeching halt. Those malfunctions can present in many different ways and be relatively tough to figure out, especially when the clock is ticking.

Luckily, the more familiar you are with your HVAC system, the more effectively you can address even the most complicated symptoms. A commercial HVAC is bigger than a residential one, but it uses the same basic technologies and concepts. A little root-cause thinking will go a long way.

Let’s take a closer look at some common commercial HVAC failure scenarios:

1. HVAC Fails to Blow Cool Air – Lukewarm Air Regardless of Settings

The most common commercial HVAC problem by far is a general failure to blow cold air, which would be reported by users throughout the service area. During this time, the system powers on as usual and continues to use a normal amount of electricity.

There are a few different possible situations here:

The most common is a lack of refrigerant. Refrigerant should always be the first thing checked when the HVAC is not blowing cool air. Even if you recently changed the refrigerant, it could still run out if there is a leak somewhere in your lines. If you suspect a leak, investigate that before refilling your refrigerant.

Clogged or dirty filters can limit cool air. If you have a case where only some parts of your facility are reporting a concern, then ductwork woes are possible. Check out the air filters within that climate zone and make sure they are clean. In older buildings, narrow ducts may become completely clogged.

Smart thermostats can behave unpredictably. Smart thermostats rely on sensors that must be kept clean and periodically replaced. It is possible for the sensor to wear out over a few years. In cases like this, the system will not activate in that area to reach the desired temperature.

2. HVAC Fails to Power On – Unresponsive Commercial HVAC

It’s easy to assume the worst when the HVAC system doesn’t power on at all. Don’t panic – this can run the gamut from a serious dilemma to a five-minute fix. You may need to track down issues elsewhere in your building system, so a totally unresponsive commercial HVAC should always be priority one.

Your thermostat may be down. Because of its electronics, a programmable thermostat should always be the first thing you check on. In addition to the odd sensor behavior noted above, it can simply be out of battery power. Switch the batteries and check its status on your building management console.

You may have a short or other electrical matter. A commercial HVAC system draws significant power at startup and this is the period of the day most likely to trip a breaker. Resetting the breaker may start the HVAC, but it’s wise to get down to the source of the behavior as soon as possible.

The system may be damaged by drain line clogs. The drain line carries moisture safely away from the HVAC unit. Just like a clogged gutter at home, a filled drain line causes a backup, so water pools up near the equipment. This leads to overflow, damaging both the equipment and the surrounding roofing material.

3. Radical Changes in HVAC Power Usage and Efficiency

It wasn’t that long ago when gauging the power usage of the HVAC system required detective work. Now, a building management system can help you identify the power usage of HVAC components as compared to your lighting. You can even see the year-on-year trends to account for seasonal changes.

If your HVAC is becoming inefficient over time, it may point to an aging compressor. The compressor is the leading factor in efficiency: It can work harder to make up for other system components, but not the reverse. When it finally comes to a stop, your HVAC system will be down until it is replaced.

Today’s commercial HVAC compressors last anywhere from 8-10 years with appropriate maintenance, but they will see a downturn in efficiency in the later years. The best way to avoid a disruptive shutdown is to prepare in advance for replacement – and that means having remanufactured commercial compressors on hand.

With an established HVAC system, you need a compressor of the exact same make and model you are replacing. But OEM wholesalers may take months to fulfill an order. A remanufactured commercial HVAC compressor arrives more quickly, offers a deep discount, and readies you for another 8-10 years.